A wide range of devices with numerous applications use precious metal plating. This process, however, can often be expensive and the precious metal is subjected to wear and tear that can eventually cause failures. Electro-Spec’s innovative methods for plating include a technological advancement known as NanoSHIELD-AU. The NanoSHIELD-AU process allows, for example a gold plated component to have a much thinner deposit without a reduction in functionality.

What is NanoSHIELD-AU?

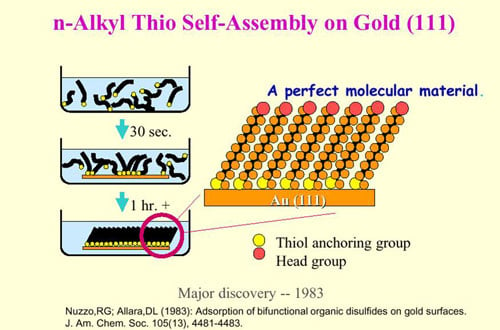

SAM is an acronym for Self-Assembled Molecules. The NanoSHIELD-AU process employs bi-Functional or multi-functional molecules that offer two or more termination groups with different functionality. Essentially, the NanoSHIELD-AU process uses molecules that offer two levels of protection. The molecules used in the NanoSHIELD-AU method can be attached to metal alloys as well as ceramic, glass, plastics, and more. Right now, NanoSHIELD technology is only being used as a post-plate surface treatment for gold and tri-alloy (Tri-M3).