The Medical, Automotive, Aerospace, Military and RF/Microwave Industries, regardless of their unique functions, often demand exceptional conductivity. Electro-Spec intends to meet the demands which sophisticated electrical components require.

Electroplating and Conductivity

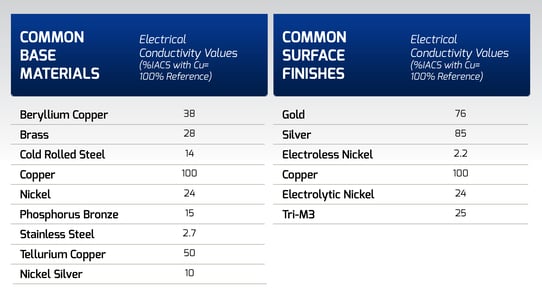

Electroplating helps improve conductivity of a raw part by enhancing its electrical properties. Electroplating can impact durability, contact resistance, solderability and corrosion resistance. When designing components for applications where conductivity is of importance, the surface finish should be chosen such that the conductivity value is appropriate for the application. Below is a table which summarizes some of the common base materials and surface finishes which are plated at Electro-Spec with their corresponding conductivity values:

Generally speaking, the higher the %IACS is, the more readily the metal will allow for the transfer of electrons from one atom to another within it and the higher the electrical conductivity of the metal will be.

Generally speaking, the higher the %IACS is, the more readily the metal will allow for the transfer of electrons from one atom to another within it and the higher the electrical conductivity of the metal will be.

An ideal electrical insulator will have a %IACS of zero. High values of electrical conductivity will typically be associated with excellent solderabilty although there are certain exceptions.

One of the most important benefits of electroplating is increased conductivity, though the results vary based on the type of material used in the process.

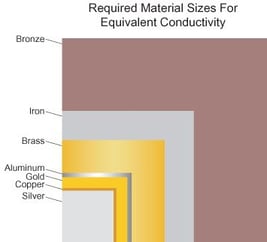

In addition, the overall result varies based on the thickness of the plated metal deposited. To the right is a visual representation of how material thickness will change the conductivity of a metal.

This is based on the cross sectional area of the metal. Metals with higher %IACS, generally speaking, will require less plating thickness than metals of a lower %IACS to achieve the same electrical conductivity.

Gold Plating

Gold plating is applied to provide excellent electrical conductivity for many industries. Not only are the electrical properties of gold plating desirable but, gold plating results in the following other desirable properties: excellent corrosion resistance, excellent solderability, ability to withstand high temperatures and superior wear resistance. Along with gold plating entire parts, Electro-Spec also offers the option to selectively plate on our controlled depth plating lines, which can result in a significant cost savings.

Silver Plating

Silver also has an excellent electrical conductivity. Silver plating offers similar results to gold plating without the additional expense. Silver also possesses other desirable qualities such as: excellent lubricity, excellent solderability, and superior thermal conductivity and ductility.

Tri-M3 Plating

An Electro-Spec specialty, Tri-M3 is a tri-metal alloy (copper, tin and zinc) surface finish that is utilized in the electronics, hardware and medical industries. Our tightly controlled, proven methods result in a precise, high-performing, consistent surface finish. Tri-M3 has a low coefficient of friction (30% less than silver) which provides superior wear resistance, along with excellent solderability, and corrosion resistance.

Innovative SAM’s Post-Plate Treatment to Increase Electrical Conductivity

Electro-Spec’s SAM’s (Self Assembled Molecules) post-plate treatment will also aid in increasing the electrical conductivity of a part while decreasing the required plating thickness to achieve other desirable properties.

A SAM’s treatment will decrease the porosity of the surface while aligning the plated metal atoms in a more uniform structure which in turn evens out the surface finish and prevents oxidation of the surface. The treatment will also provide excellent corrosion resistance and solderability.

The specific performance and selection of electroplating finishes depends upon multiple factors. As you research the best choice for your next project, remember to consider:

- The substrate to which the plating will be applied

- The intended product use (functional, decorative, or both)

- ASTM or other specifications that need to be followed

- Intended life span of the part and plating

- Environment the part will be exposed to

The material selection phase and host of electroplating solutions available are vast, and we’re here to help. The asdfasdfasdf Electro-Spec Library offers digital resources for a range of applications and projects.

For more help on selecting the appropriate plating for your next project, click here to contact us.

Information, Image and Table compiled from:

Parkinson, Ron. Properties and Applications of Electroless Nickel. Toronto: Nickel Development Institute, 1997. Nickelinstitute.org. Web.

"IHI Connectors Mechanical Screw Wire & Cable Terminal Lugs." IHI Connectors Mechanical Screw Wire & Cable Terminal Lugs. N.p., n.d. Web. 08 Oct. 2015.

"Electrical Conductivity of Materials." - Blue Sea Systems. N.p., n.d. Web. 08 Oct. 2015.

Products, Furez. IACS of Metals, Alloys and Solder (n.d.): n. pag. Web.