When precision plating matters, even minor issues can cascade into significant performance failures and costly rework. After decades of serving aerospace, automotive, medical, and electronics manufacturers, we've seen recurring plating challenges that disrupt production schedules and compromise component reliability. Understanding these problems and their root causes is essential for engineers specifying plating requirements and manufacturers selecting the right plating partner.

Why Tri-M3TM Tri-Alloy Plating Is Enabling Next-Generation Technology Performance (7 Use Cases)

Engineers developing next-generation RF connectors, telecommunications infrastructure, and high-frequency components face a persistent tradeoff: silver delivers superior electrical conductivity but tarnishes rapidly and drives up costs, while nickel offers durability and corrosion resistance but introduces magnetic interference that degrades signal quality. This compromise has constrained design decisions for decades, forcing manufacturers to choose between suboptimal performance and elevated material costs.

When your engineering prints call for "nickel plating" without specifying the chemistry, you're leaving critical performance decisions to interpretation. The choice between matte (sulfamate) and bright (sulfate) nickel isn't only about cosmetics. It's an engineering decision that impacts mechanical properties, coverage uniformity, and long-term reliability in ways that can make or break your application's performance.

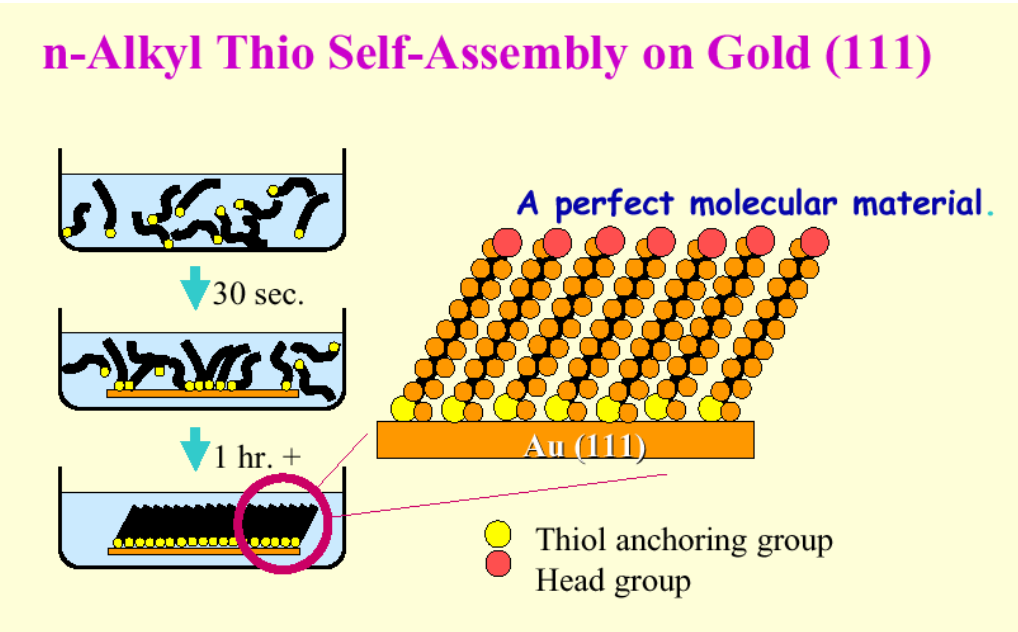

As manufacturing industries push the boundaries of miniaturization, performance, and cost efficiency, traditional surface finishing approaches face mounting limitations. Components in aerospace, telecommunications, medical devices, and advanced electronics require surfaces that deliver exceptional performance characteristics while meeting increasingly stringent dimensional tolerances. Self-assembled monolayers (SAMs) represent a breakthrough approach to surface engineering that addresses these challenges through molecular-level precision.

You've specified the perfect plating material. Your part geometry is optimized. The service provider follows all the right standards. Yet when the parts arrive, you discover adhesion failures, contamination issues, or inconsistent coverage that compromises performance and forces expensive rework.

Corrosion and oxidation can compromise part reliability in aerospace, medical, and high-performance applications. Whether it's ensuring a surgical instrument maintains its sterility or an aerospace fastener performs reliably throughout its service life, the right surface treatment makes the difference.

Specifying the Right Plating for Telecom Connectors: Gold vs. Silver vs. Nickel vs. Tri-M3™ and HPEN

Connector plating can make or break network performance over the years of service. Every plating decision is a balancing act between conductivity, corrosion resistance, magnetic properties, and wear life, all of which impact uptime, signal clarity, and maintenance cycles.

In safety-critical industries like aerospace, medical, and telecommunications, engineers have to consider factors beyond base material and design for dependable component performance. For example, the right plating finish can make the difference between years of flawless service and early failure.

For engineers working with mission-critical parts, boreholes, inner diameters (IDs), and tapped holes are often where performance lives or dies. But when it comes to plating these internal features, even small design decisions can have outsized consequences for quality, cost, and timeline.

When it comes to high-reliability components, plating isn’t just the finishing touch—it’s a critical performance factor. But for parts with complex geometries, achieving consistent, functional, and spec-compliant plating can be far from simple.