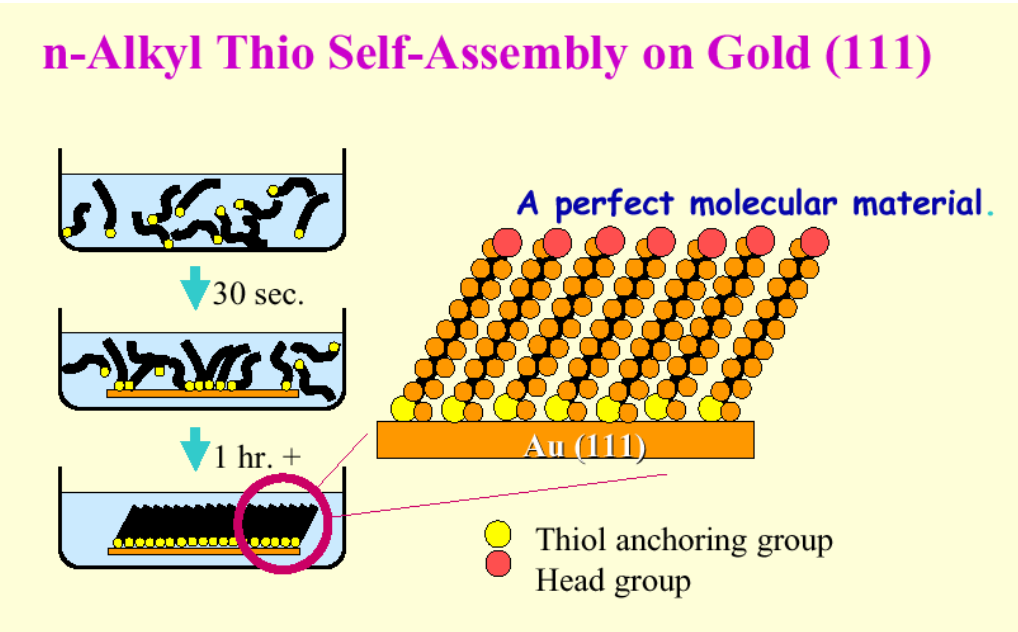

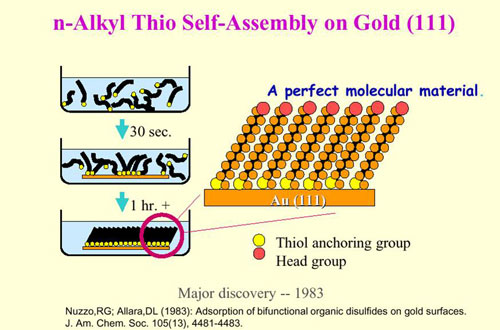

As manufacturing industries push the boundaries of miniaturization, performance, and cost efficiency, traditional surface finishing approaches face mounting limitations. Components in aerospace, telecommunications, medical devices, and advanced electronics require surfaces that deliver exceptional performance characteristics while meeting increasingly stringent dimensional tolerances. Self-assembled monolayers (SAMs) represent a breakthrough approach to surface engineering that addresses these challenges through molecular-level precision.

A wide range of devices with numerous applications use precious metal plating. This process, however, can often be expensive and the precious metal is subjected to wear and tear that can eventually cause failures. Electro-Spec’s innovative methods for plating include a technological advancement known as NanoSHIELD-AU. The NanoSHIELD-AU process allows, for example a gold plated component to have a much thinner deposit without a reduction in functionality.

What is NanoSHIELD-AU?

SAM is an acronym for Self-Assembled Molecules. The NanoSHIELD-AU process employs bi-Functional or multi-functional molecules that offer two or more termination groups with different functionality. Essentially, the NanoSHIELD-AU process uses molecules that offer two levels of protection. The molecules used in the NanoSHIELD-AU method can be attached to metal alloys as well as ceramic, glass, plastics, and more. Right now, NanoSHIELD technology is only being used as a post-plate surface treatment for gold and tri-alloy (Tri-M3).

Precious metal plating is an expensive process, especially because the standard method for improving corrosion is to increase the plating thickness. With self-assembled molecules (SAM’s), however, metal plating can be reduced significantly without losing corrosion protection. In addition to enhanced corrosion protection, SAM’s will also allow plated components to have increased conductivity.

Conductivity and Reduced Metal Thickness

Precious metal plated items, and in fact any plated item, experience increased resistivity because of uneven surfaces. This resistivity becomes even worse when the plating is thicker. Most manufacturers are forced to increase the thickness of the plating to stop corrosion, but this can decrease the performance of the item while increasing the cost of production. SAM’s addresses both of these issues. The molecular shield provided through SAM’s helps slow the corrosion process down and allows manufactures to use a thinner plating deposit.

When this happens, the conductivity of the plated item improves as well. This is because the plating is thinner and the molecular shield provides a more even surface that lowers resistance. Contact resistance due to uneven surfaces caused by thicker plating creates localized heating. With SAM’s, however, this problem is solved because the molecular shield fills the voids in any uneven surfaces of the plated component. The surface then becomes smoother, enhancing conductivity.

A wide range of devices with numerous applications use precious metal plating. This process, however, can often be expensive and the precious metal is subjected to wear and tear that can eventually cause failures. Electro-Spec’s innovative methods for plating include a technological advancement known as SAM’s. The SAM’S process allows, for example a gold plated component to have a much thinner deposit without a reduction in functionality.

What is SAM’s?

SAM is an acronym for Self-Assembled Molecules. The SAM’S process employs bi-Functional or multi-functional molecules that offer two or more termination groups with different functionality. Essentially, the SAM’S proces s uses molecules that offer two levels of protection. The molecules used in the SAM'S method can be attached to metal alloys as well as ceramic, glass, plastics, and more. Right now, SAM’S technology is only being used as a post-plate surface treatment for gold, silver and tri-alloy (Tri-M3).