Rework and scrap pose critical challenges to manufacturers, particularly in industries requiring precision and reliability. Defective or out-of-spec components lead to increased costs, production delays, and strained supplier relationships. For safety-critical components in highly regulated industries like aerospace and automotive, these issues are especially damaging, creating bottlenecks that disrupt the supply chain and delay deliveries to OEMs.

Electro-Spec has been providing award winning electroplating and electroless plating services to customers for over five decades. This includes applications for lifesaving and safety critical components. Plating is available in precious and semi-precious materials including gold, silver, nickel, copper, Tri-M3TM (Tri-Alloy), electroless and electrolytic nickel. This short article discusses these plating options, as well as their benefits and examples of industries that they are often found of use within.

Products Finishing magazine names Electro-Spec to the ‘Top Shops” list

CINCINNATI, Ohio – Electro-Spec, Inc. has been named one of the best finishing shops in the U.S., according to an industry benchmarking survey conducted by Products Finishing magazine, a trade publication which has covered the industry since 1938.

Accounting for Plating Thickness in Assembly Design

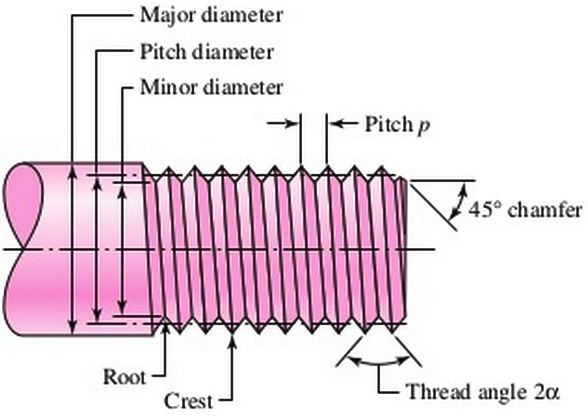

The main consideration when plating threaded components would be to ensure that the plated threads properly fit into their mated counterparts. As shown in Figure 1-1, the dimensions to consider here would be the diameter and pitch of the threads. This translates into the tolerance of the plated coating being accounted for within the assembly because the plated coating will slightly change the geometry of the threaded component. The thickness of the plating should be accounted for when the part is designed. The most ideal location to account for the plated coating would be within the specifications of the mating part, including diameter and pitch. Of course, certain calculations are required to determine the slight change in the diameter or some other dimension of the mated part which will not impact the overall strength of the assembly. But, this is a calculation that should be performed before arbitrarily designating a plating thickness.

The use of gold plating in the electronics industry has been an ongoing part of the expansion of more complex digital electronics and equipment throughout many industry sectors. According to BullionStreet, over 320 tons of gold are used each year in the electronics industry. This includes gold in PCs, mobile phones, tablets and other devices. The overall use of gold in electronics is via gold plating. Gold plating is primarily used on contacts for switches, relays, and connectors